On the way to simple, fast and safe vaccination

Bioneedle Drug Delivery has commissioned a new production line for the bioneedles of an injection system that makes vaccination simpler, faster and safer. The line was built by technology developer and producer Demcon in Enschede. Demcon acts as a development and production partner for the innovative Bioneedle technology. The funding came from a large number of Dutch investors, including Demcon Investment. Bioneedle Drug Delivery, headquartered at the Leiden Bio Science Park, was formed in 2004 by biologist and vet Gijsbert van de Wijdeven. He had discovered a new method of vaccination, using ready-made bioneedles made of biodegradable material. The hollow needles are filled with high concentrations of medicines or vaccines that are stabilized by the material, which increases their shelf life and means that they need no refrigeration. The needles are injected subcutaneously (under the skin) or into a muscle with an applicator that works with compressed air. The body fluids present dissolve the needle within a few minutes, so that the medicine/vaccine is delivered fast. This injection method is simple, fast and safe, and works more efficiently than the conventional method with syringes, needles and bottles. The advantages include the fact that injection is clean and painless, that no used disposable syringes are left over and that there is no need to refrigerate the medicine/vaccine. The transportation and storage volumes are also lower, by a factor of 160, which means that enormous cost savings can be realized.

National Icon

At the time, due to complex regulations, veterinary application of the bioneedle proved not to be feasible. Van de Wijdeven therefore focused on human healthcare, partly at the request of the World Health Organization (WHO). The WHO saw potential for large-scale vaccination campaigns because there was no need for refrigeration. This makes logistics far simpler, which is important in developing countries with limited infrastructure, and in the case of pandemics such as Covid-19, it is of global importance. Partly for that reason, Bioneedle was classed as a National Icon in 2014, which led to government support and international attention for the business. The development of the new injection system continued, with ups and downs, and in 2019, Wolf Ondracek joined the company as CEO.

Boost

With 30 years of experience in clinical research for the pharmaceutical industry, Ondracek had to give a new boost to Bioneedle and search for partners and investors. “We were working on an application for medicines, but when the pandemic arose, it became obvious that we were going to focus on vaccines,” he says. “Because of this, we had a lot less explaining to do about the importance of being able to inject and vaccinate fast.” Bioneedle has already conducted pre-clinical studies for frequently used vaccines, for instance for polio, tuberculosis, hepatitis and influenza. “Those studies went well. There turned out to be an enormous improvement in the stability of vaccines at normal environmental temperatures and the effectiveness in animal models was similar to, or better than that of the conventional formulation. This result concerned protein-based vaccines, but we are now looking at other types, such as mRNA and live virus vaccines. For this, we are researching how they stabilize in bioneedles and whether we still need to adjust the material composition of the needles.”

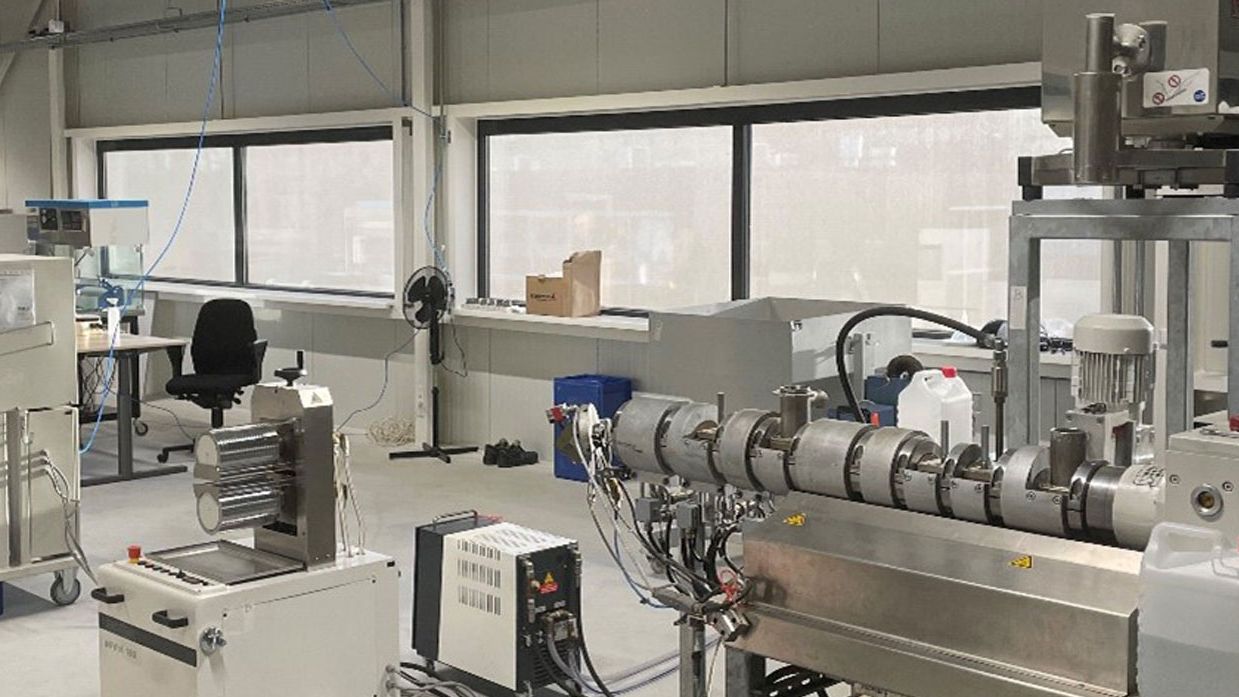

Production line

Ondracek came into contact with Demcon 18 months ago, via his network. “Making small, pointed bioneedles from natural materials, including starch, is a complex process” he says. “The machine line needed is very large and we were looking for a suitable space for that.” That space and knowledge of production technology was available at Demcon, explains Demcon’s new Business Development Manager Jan Leideman. “In order to be able to start up production quickly, we used injection molding machines of Demcon Injection Moulding, which were combined with existing Bioneedle machines to create a complete line.” The new line forms a step up to the final production line that will produce bioneedles for clinical use. This has to take place in an environment that meets the highest standards, in accordance with Good Manufacturing Practice (GMP) rules. Ondracek explains: “We will conduct intensive talks with Demcon to that end, because the existing machines are not GMP-proof. They’re suitable for production for pre-clinical studies, but not for clinical trials and pilot programs for market authorization. The line ultimately has to be scalable, because if the bioneedle is successful, we will be producing huge numbers of them.” Leideman adds: “That requires automation and robotization; typical expertise of Demcon Industrial Systems. We have also already gained experience with production in biotechnology projects.”

Investment round

Ondracek says that Bioneedle has now successfully completed an initial investment round. “We raised funding from friends and family – as many as 17 parties in all. The Roland Berger consultancy helped with that, by putting us in touch with Dutch angel investors. We needed money to reach three milestones: starting production again, finding a new vaccination platform for that, such as the live virus vaccines, and finding out about everything we need in order to be able to conduct an initial clinical trial.” Leideman adds: “Demcon, through its investment company Demcon, also made an investment and has joined as a shareholder. The most important thing is that with an investment like this, we are committing to the technology of Bioneedle. That’s a role we frequently play: our commitment helps to ensure that financial parties such as private and public investment funds make bigger follow-up investments in start-ups.”

Developing solutions together

Dennis Schipper, Managing Director of Demcon, calls the involvement with Bioneedle a good example of ‘creating shared value’. “Our goal is to develop technological solutions for social challenges together. In this case, it’s even about a major global problem, for which Bioneedle has a solution that can save countless lives. Another thing that I like about this partnership is that other Demcon companies are involved in it too. In addition, our professional approach to medical product certification is once again paying off. And finally, through Bioneedle, we gain more visibility in Leiden, where we want to become involved in developments in biotechnology and medical technology. I’m proud that our partnership has already led to the start of the new production line.”