complete coating process, complete connectivity.

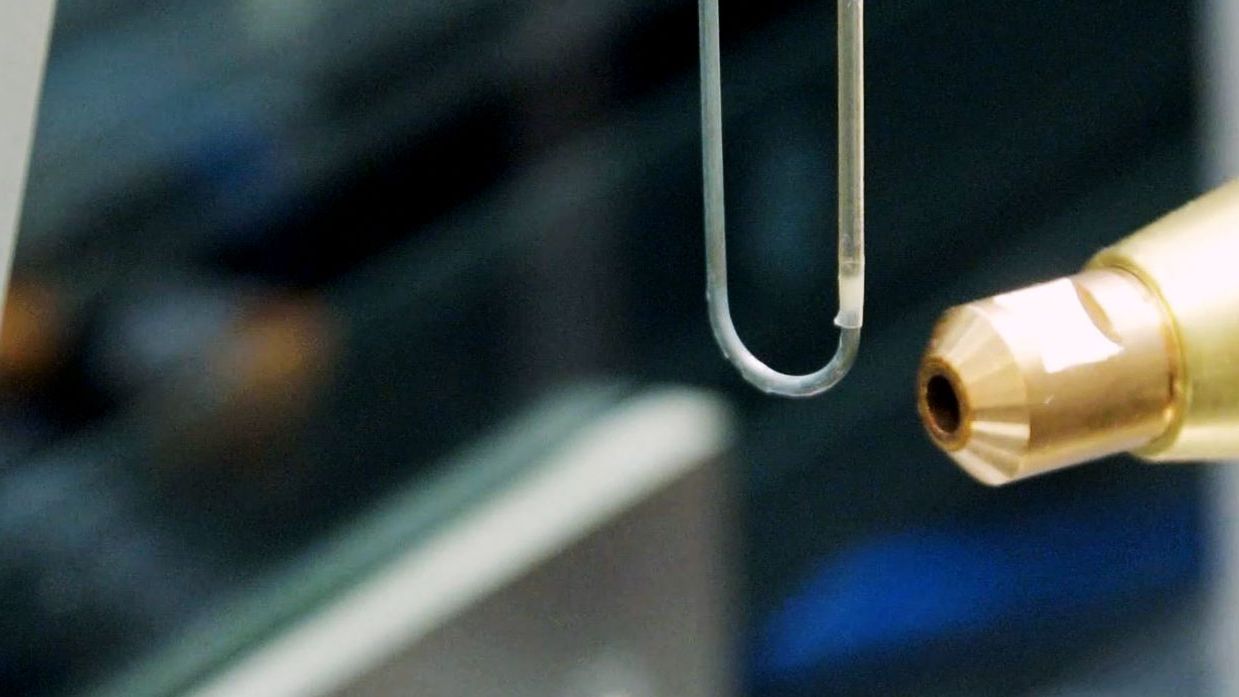

Encapson’s Sono-Coat® technology gives medical instruments excellent reflectivity to ultrasound and therefore better visibility. To apply the coating, Encapson developed three process steps: plasma treatment of the surface for good adhesion, the actual coating and the drying. We developed a machine, the SonoLine 03, for the complete process.

The modular design of the SonoLine 03 is based on our standard platforms, Smart Machine Base (SMB) for the hardware and BRIX for the software. We linked two SMBs and equipped them with process-specific modules. Operators manage the infeed and outfeed of the instruments, which are guided along the various process steps by a conveyor belt. For optimal configurability, each module features complete connectivity, with remote I/O, EtherCAT, power and compressed air. Because coating requires a clean environment, we have made the machine ISO 7 cleanroom compatible.

highlights

- SMB and BRIX standard platforms

- freely configurable machine

- ISO 7 cleanroom compatible

- full traceability of production parameters

accurate timing and positioning, strict control.

The maximum lead time for the complete process in the machine is one minute. This is determined by the slowest process step. Accurate timing prevents the completion of previous steps before the slowest step is ready to process the next product.

Each instrument must be dipped to the same length into the coating fluid, with the level dropping as the fluid is slowly consumed. We have therefore added fluid level measurement and tip detection of the product to be coated. Due to the accurate positioning of the instrument, the coating length can be precisely controlled to within 0.1 millimeter.

The machine control takes into account the strict requirements for medical applications. For example, we have provided full traceability of the production parameters and authorized management of the coating recipe. An operator may adjust certain parameters, but only a coating specialist is authorized for other parameters. We have set up the access control for the recipes accordingly.

“we have made the machine fully modular and freely configurable.”

The development of the SonoLine 03 was the first customer project with our SMB and BRIX standard platforms. It involved dealing with very different modules for the three process steps. Nevertheless, we succeeded in building the machine in a fully modular way and making it freely configurable. Uniquely, no matter how we add modules or change their order, the machine will always work.