integrating and automating.

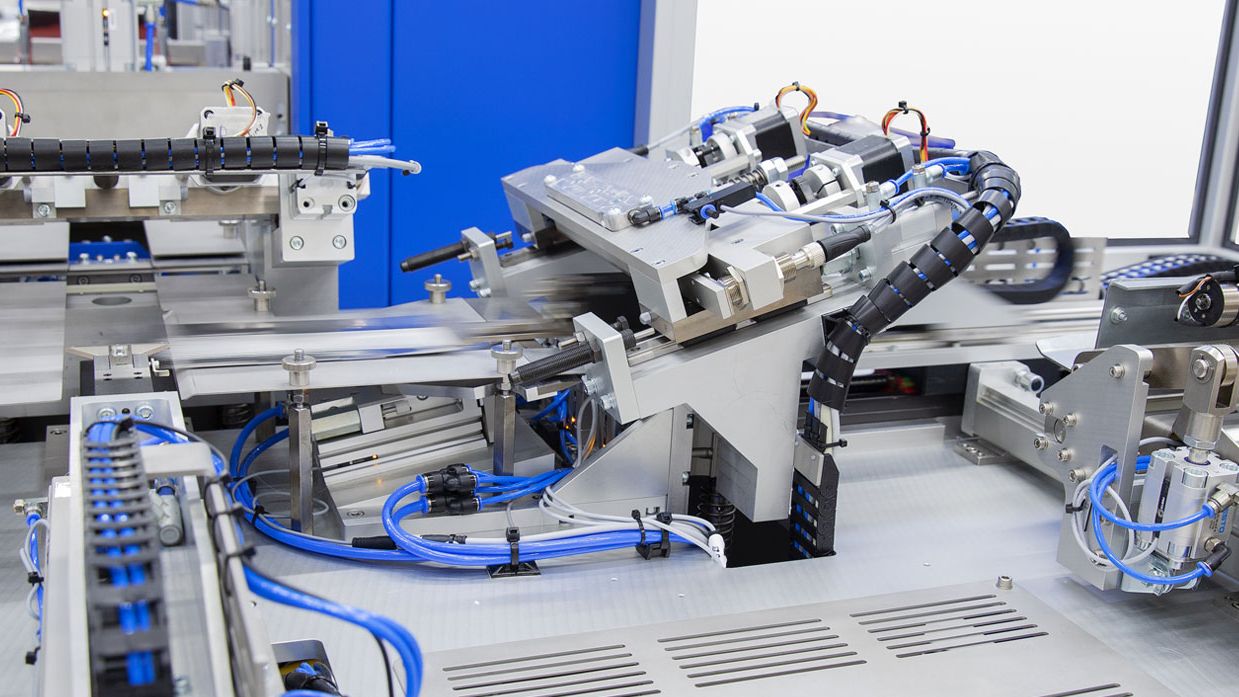

For the treatment of burns, the doctor cuts the patient’s own skin into “skin islands” of 3 by 3 millimeters. These are placed on a carrier that the doctor can stretch to the desired size to cover a wound as much as possible. The carrier, a laminate of aluminum foil and nylon, must first be laminated and folded (pleated). At Humeca, this was done with a few machines and a lot of manual work. For consistent quality and higher capacity, Humeca wanted to further integrate and automate the pleating. We built a pleating machine for this medical gauze that could improve the stability, quality and possibilities of their production.

highlights

- new folding principle

- complete automation, high capacity

- cleanroom compatibility

- machine safety and user-friendliness

laminating and cutting, folding and rolling.

We developed a machine that first takes care of the lamination and cutting, using a guillotine knife, and then the pleating. Finally, the folded carrier is rolled. The material thickness is critical for accurate and reproducible folding; the final carrier must measure 42 by 42 millimeters, with a tolerance of maximum +/–0.5 millimeters. We devised a new folding concept and built a proof-of-principle for research into, among other things, the required degrees of freedom for the knife. In the end, we built a complete machine, with two pleating stations and including process steps such as laminating, cutting and rolling. In addition, we ensured cleanroom compatibility, machine safety and user-friendliness of the operator interface.

“we work precisely and pragmatically.”

This project demonstrates that we master automation for very diverse sectors and that we do not limit ourselves to standard machine building and industrial automation. We enjoy devising smart solutions for a medical application. Having already been involved in the project at an early stage, we could contribute our broad expertise and thus realize a pleating machine for laminated medical gauze. We worked precisely where necessary and pragmatically where possible.