challenges faced by production companies.

Many production companies pursue operational excellence to stay profitable as competitors enter the market with new products. Also, a new competitor might shake-up the market with a brand new production site, taking advantage of all benefits offered by modern technology to put sales price under enormous pressure.

The following challenges stand out as significant barriers to operations:

-

Workforce Transition – As experienced operators retire, recruiting and retaining skilled talent capable of maintaining precision and quality becomes a growing challenge, impacting production reliability.

-

Dated Technology – Most existing factories were built in a different era, before industry 4.0 or even 5.0 technologies existed, limiting the availability of data and use of intelligent algorithms.

-

High Complexity – With a history of repairs, additions and modifications to the originally designed factory, it becomes increasingly complex to know how changes affect quality, putting a brake on innovation.

Companies need to revise their strategies to reduce operator dependency, incorporate innovation and invest in modern technologies to stay profitable in the long term.

the autonomous factory.

Striving for operational excellence is often based on a continuous improvement process. They come in various forms using different methodologies, but always provide a systematic approach to making small steps of improvements. It is a well-proven optimization tool, but has the tendency to limit innovation. You may find the best spot on your island, but are unaware of better spots on a nearby island. Possibly it is only a river you need to cross and you don’t even need a boat.

To do better, we need to not only analyze and resolve issues in a reactive manner, but attempt to predict failures in advance. Once a sufficiently accurate model is obtained to prediction the future, we can:

- Prevent bottlenecks from occurring by iteratively optimizing the planning and simulating operations

instead of failing to deliver in time as a consequence of ad-hoc decisions to resolve unplanned situations - Eliminate yield loss by predicting quality of a produced batch in advance and adjusting process parameters

instead of measuring quality end-of-line, resulting in scrapped batches or significant rework costs - Reduce unplanned downtime because equipment and tooling health are monitored continuously

instead of detecting tool wear through an increase of rejects at quality control

The ultimate goal of an autonomous factory is to increase productivity: make more with less.

the digital foundation.

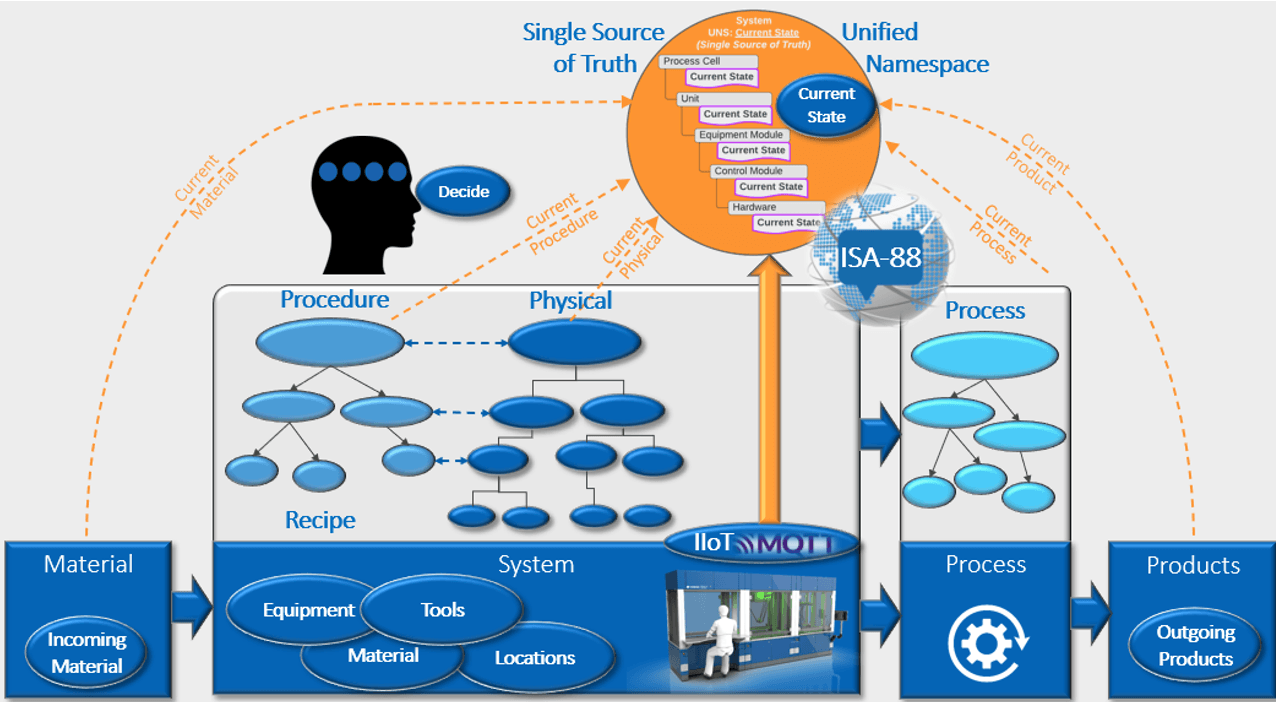

A factory truly becomes digital when it is built on a solid but flexible foundation. This is achieved by creating a digital foundation for machines that seamlessly connects to the rest of the factory. Key elements include standardization within the mechatronic design, a uniform data model, and integration with higher systems using Industrial Internet of Things (IIoT). This provides insight into the system, process, and product - essential for the step towards predictive operations. Industry standards play a crucial role in the digitalization of the factory. ISA-88 focuses on structures within the machines, while ISA-95 addresses the factory level. Following these standards creates a consistent and efficient workflow that forms the basis for integration and collaboration between different systems and departments. An important aspect of this digital foundation is the use of IIoT with protocols such as MQTT. The Unified Namespace concept, applied with MQTT and based on industry standards (ISA-95/88), ensures uniform and standardized data exchange within the factory. This protocol enables real-time communication between machines and applications creating a single source of truth, which is essential for monitoring and optimizing production (and business) processes.

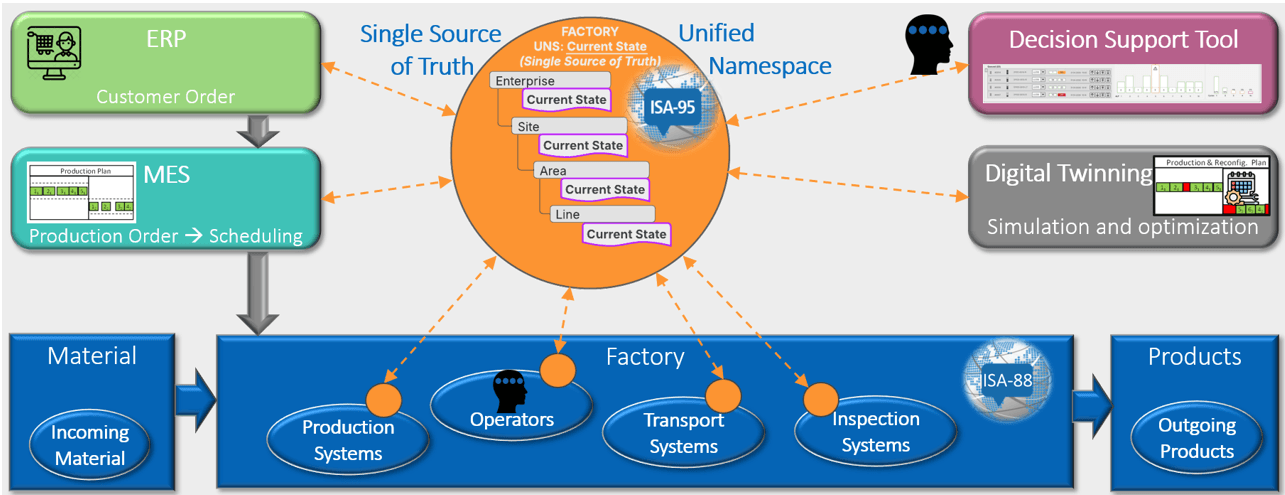

By harnessing the power of ISA-88 standards on the factory floor, the groundwork is laid for a seamless integration with ISA-95 at the factory level. Standardized data from various factory floor, encompassing every machine and process, combined with factory-level applications (like MES/ERP) feeds into the ISA-95 framework, creating a unified namespace at this higher level. This unified namespace serves as a central repository of information, ensuring that data from ERP and MES applications is consistently structured and readily accessible.

At this juncture, leveraging the capabilities of artificial intelligence (AI) and machine learning (ML) becomes transformative. AI and ML can analyze vast amounts of data collected from the ERP, MES, and factory floor systems to identify patterns, predict outcomes, and optimize processes. These insights enable predictive maintenance, enhance quality control, and streamline operations, ultimately driving efficiency and productivity. The integration of AI and ML into the unified namespace provides a holistic view of the factory operations. For instance, predictive analytics can forecast equipment failures before they occur, allowing for preemptive maintenance that minimizes downtime. Similarly, real-time quality monitoring ensures that any deviation from the desired product specifications is immediately addressed, reducing defects and rework costs. In essence, the combination of standardizing data (using ISA-88/95), real-time data from factory floor systems, and advanced AI/ML analytics creates a robust digital foundation. This foundation not only supports the immediate operational needs of the factory but also provides the agility and flexibility required to adapt to future technological advancements and market demands.

predictive operations.

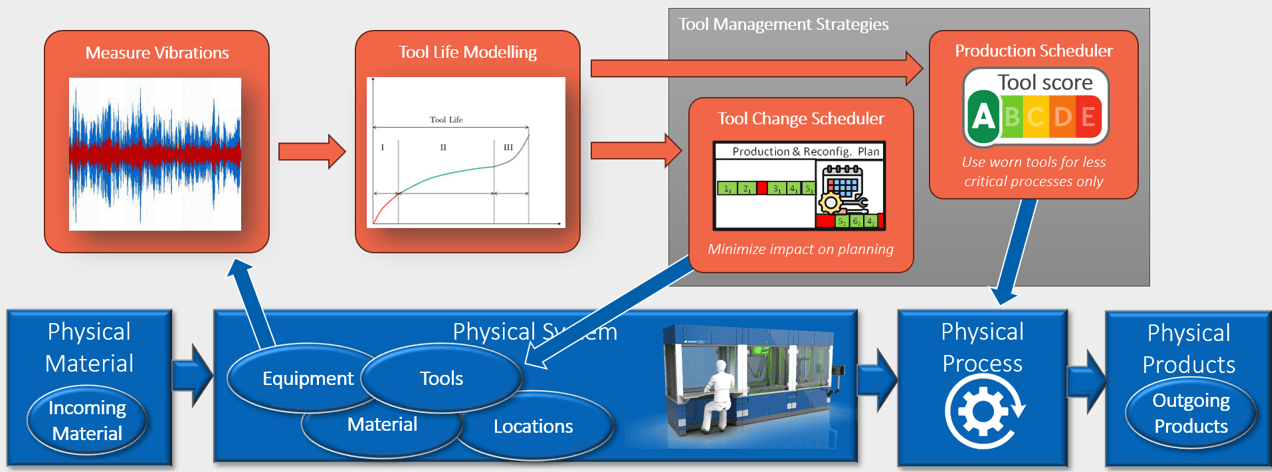

Tool usage can be monitored and managed to ensure optimal performance. By tracking tool usage in real-time and predicting wear and maintenance needs, operators can prevent unexpected failures that lead to costly downtimes. The data collected allows for precise adjustments and timely interventions, optimizing tool lifespan and performance. Predictive operations are not solely about the lifespan and performance of tools; they are equally about maintaining product quality while optimizing the balance between cost and quality. By continuously monitoring and analyzing the production process, adjustments can be made in real-time to ensure optimal performance and minimal defects. This holistic approach encompasses both tools and products, ensuring that every aspect of the manufacturing process is fine-tuned for efficiency and excellence.

Efficient tool management is critical in maintaining the productivity and quality of an autonomous factory. With continuous monitoring and predictive analytics, each tool's condition is assessed, and maintenance schedules are dynamically updated to reflect actual usage and wear patterns. This proactive approach minimizes the risk of tool-related defects and ensures consistent product quality.

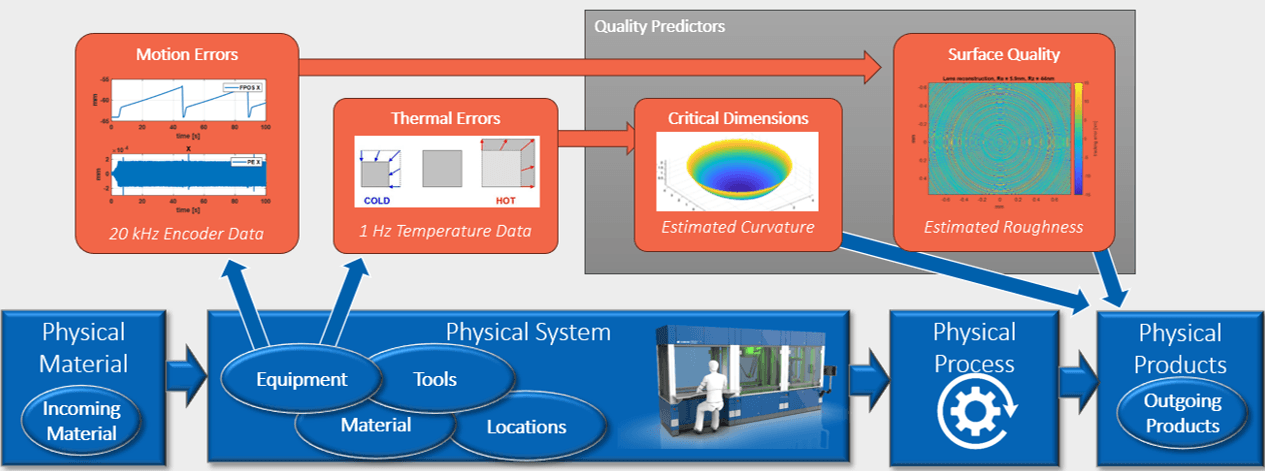

Predictive Quality operations leverage real-time data from various sources, such as motion (encoder) data and temperature data, to ensure the surface quality of products aligns with planned specifications. By continuously comparing actual surface quality data with predefined standards, operators can detect deviations early and make necessary adjustments. Motion data, collected from encoders, provides precise information about the movements and positioning of production equipment. This data helps in monitoring the consistency and accuracy of operations, ensuring that each product meets the desired shape and surface quality. For instance, if an encoder detects a slight misalignment, an immediate correction can be made to prevent defects.

Temperature data plays a crucial role in maintaining product quality, especially in processes sensitive to thermal variations. By monitoring the temperature at various stages of production, the system can adjust cooling or heating mechanisms or compensate to maintain optimal conditions. These adjustments are critical in processes like CNC machining, where fluctuations in temperature can significantly impact surface finish. Integrating motion and temperature data into the predictive quality framework allows for a holistic approach to quality management. This continuous feedback loop ensures that every product not only meets but exceeds quality standards, minimizing defects and optimizing overall production efficiency. By adopting predictive quality operations, manufacturers can achieve a seamless balance between high-quality output and cost-effective production.

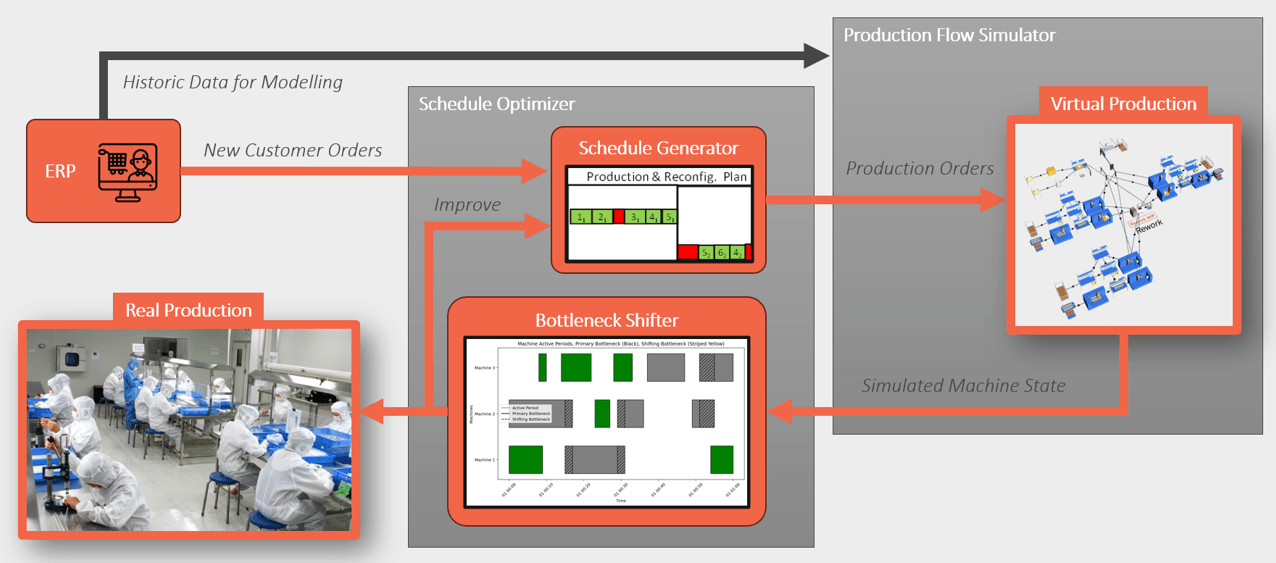

Production flows can be modelled using Discrete Event Simulation (DES), an approach that is very suitable to capture the statistical variance present in manufacturing. In addition to the nominal duration of a specific process step, a probability distribution can be selected to model random variations or specific events that can cause delays. Using historical operational data that is typically available in ERP or MES, this model can be parametrized to accurately simulate the flow of new orders through operations. In itself, this ‘Production Flow Simulator’ could be useful to provide customers with much more accurate lead times based on actual loading of equipment. Next we add a schedule generator, capable of generating a simple production schedule based on a set of customer order and some basic metrics to prioritize the resulting production orders. Instead of directly sending this generated production schedule towards the work floor, we first do a virtual production run using our ‘Production Flow Simulator’. Based on this simulation, we can detect bottlenecks and suggest improvements the schedule generator. After a number of these simulation loops, which typically only take several seconds to complete, we find an optimized production schedule which is then released to the real factory.

starting the evolution.

With the ambition set to transform into a digitized and autonomous operation, how do you start? Even though the concept is quite simple, it is impossible to transform your complete operation in a single day. In the end it is not just about rolling out new technology, but also about changing people and their way of working, which typically take an evolution, not a revolution to be embedded in an organization.

Luckily, the virtual factory can safely be developed in parallel to an existing operation and gradually grow over time. Usually the hardest part is to start building the digital foundation, because a significant effort may be needed to extract data from outdated control hardware, while no immediate benefits are observed by the rest of the organization. If too difficult, a separate sensory network may be installed to obtain data without interfering with existing operations.

To take the first hurdle of starting the evolution, we advise to start as small as possible while aiming to create a demonstrator with sufficient impact. Focus on a single use-case that requires data from only a few sources, but which can really make a difference in daily operations resolving a problem that has been hard to tackle:

- Setup a small but scalable data operations

- Unlock some operational data

- Successfully demonstrate the use-case

As tangible benefits become visible, people throughout the organization will propose use-cases to make their work easier, setting-off a snowball effect by learning and gaining new knowledge. As the snowball revolves, simply repeat steps 2 and 3, while maintaining and expanding the data operations.

staying ahead of competition.

The next industrial revolution is powered by data, which is mandatory for leading manufacturers to stay competitive in a global market. Specifically, operational excellence is obtained through 3 key drivers:

- Gain Knowledge – secure knowledge from key-persons into decision-supporting applications

- Improve Quality – deeper understanding of processes leads to better quality and less waste

- Increase Output – algorithmic optimizations maximize the output from existing equipment

In conclusion, the transition towards a data driven operation is not simply a process of replacing operators by algorithms. It requires a new competences and skills to be developed throughout the organization. The companies that succeed in this transformation become more resilient to external threads and can secure their place as leaders in operational excellence.

contact.

Would you like to exchange thoughts about your production process? Please reach out so we can schedule an online meeting or plan a visit.

DEMCON Industrial Systems Groningen B.V.

Blauwborgje 31, 9747 AC GRONINGEN, Nederland