1. Challenges Faced by Production Companies

Many production companies have protected their margins by tailoring their products and service more and more to specific customer needs. As a consequence the number of product variants has exploded, making it more difficult to benefit from automated production.

These companies now face a range of persistent challenges that threaten their competitiveness in an increasingly globalized and demanding market:

- Modern customers demand tailored products that match their unique needs, yet expect pricing comparable to mass-manufactured goods, stretching the limits of manual operations.

- Competitors worldwide are leveraging advanced manufacturing techniques to deliver higher quality products at lower costs, putting pressure on companies relying on manual labor to keep up.

- Experienced operators are retiring, and recruiting and keeping new talent capable of maintaining the same level of precision and quality has become increasingly difficult, hindering production capacity and reliability.

These symptoms collectively signify the need for a transformative approach to sustain quality, efficiency, and customer satisfaction in high-mix production environments.

2. Why automation of high-mix manufacturing is hard

Transitioning to automation does not mean simply replacing human hands by robotic arms. Unfortunately this is what often happens when companies take first steps in automation. Once – after much hard work – the automated solution is deployed in operation, it fails to increase the productivity. For example, an operator still needs to select the right parameters or feed in and out the materials per batch. As a consequence, it stops within 5 minutes after an operator goes off for lunch. Maybe the solution still contributes to a more consistent quality, but the majority of potential is left untouched.

For automation to become a game-changer, the following goals should be set:

- Autonomy – How long can the system continue without human intervention? Boost productivity with a system that continues production unattended during the nights or in the weekend.

- Quality – Can the system produce consistent quality and monitor in case of deviations? Computers typically beat humans for consistency, but we humans detect many issues otherwise unnoted.

- Flexibility – Can the system handle all (current and future) product variants and production volumes? Both the mix and volume of orders varies over time, demanding modularity and scalability of your factory.

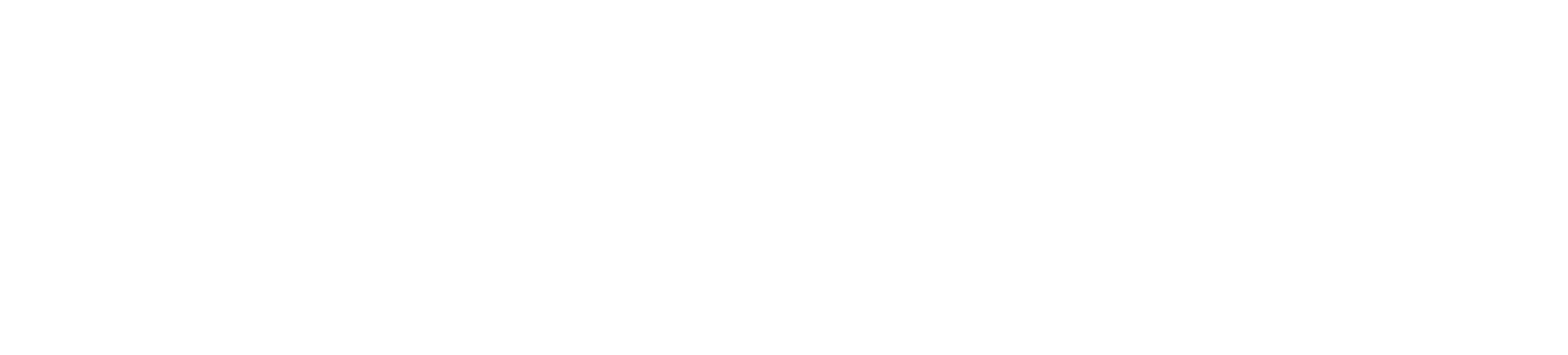

As an illustrative example, let us consider an assembly process of medical disposables that are made-to-order. Several product variants are depicted, varying in complexity and components used.

The processes that take place are:

- Picking injection molded base parts

- Glueing tubes into the base part

- Placing clips on the tube

- Adding special items such as bags or filters

- Rolling up tubes to fit the packaging

- Sterilized packaging

Product configurations may include up to 60 components, with each component having different variants such as the part geometry and tube length. This leads to an overwhelming amount of possible variants. However, by looking at the processes we managed to boil it down to just 6 generic processes.

3.The flexible factory architecture

Instead of looking for a repetitive human task and begin by automating that isolated process, we prefer to begin with the end in mind. Once the factory architecture is designed, it becomes much easier to plan incremental steps of automation that do not put current operations at risk.

identify processes.

For mass production, we tend to first look at the product being manufactured and develop a dedicated production line around it. But in case of high-mix production, this paradigm shifts as the number of products to consider is simply too large. Instead we aim to identify different processes first.

flexible transportation of carriers.

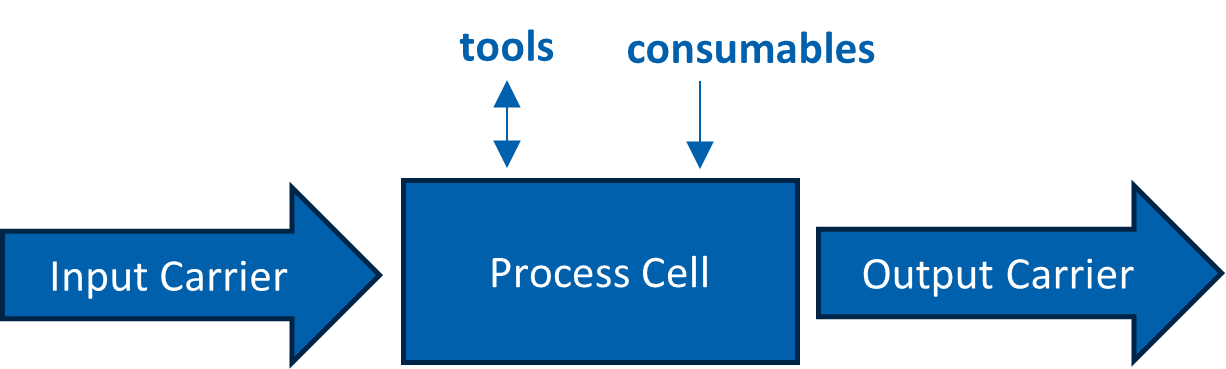

The next step is connecting the individual process cells using a flexible transport system, for which many commercially available options exist to match required dimensions, capacity and flexibility. Several examples are depicted below.

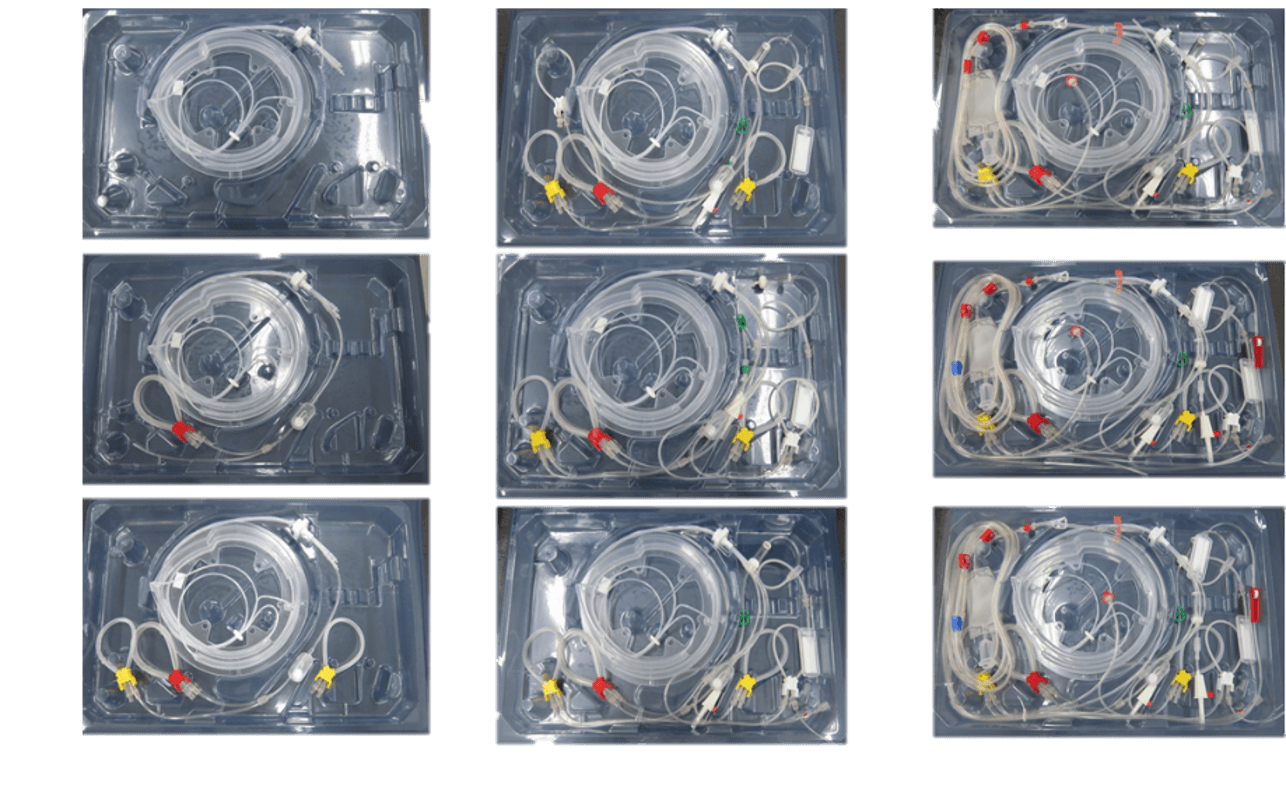

Contrary to the process cells, the transport system can be tailored to specific product configurations using a carrier. This ensures that components and intermediate products are always at a well-defined position with respect to the transport unit, making automation tasks such as pick-and-place significantly easier.

.png)

optimize for automation.

Lastly, we zoom-in at each of the defined process cells to optimize their flexibility. The goal is to design generic process cells that can execute their process on any product variant without manual reconfiguration or reprogramming. The infeed of components using the transport system should be carefully traded off against usage of generic consumables. Typically it is most efficient to use consumables that are manually supplied to the process cells in bulk containers, as long as the number of consumable variants is small.

In some cases it is not as obvious as of whether a material is an ‘input component’ or a ‘consumable’. In a fastening cell, the bolts can be fed to the process using a vibratory bowl feeder for example. In which case the bolts are considered consumables. However, if each product requires different types of bolts, it may make sense to include the bolts on the input carrier. A separate process cell could be designed for order-picking the right bolts for a specific product configuration.

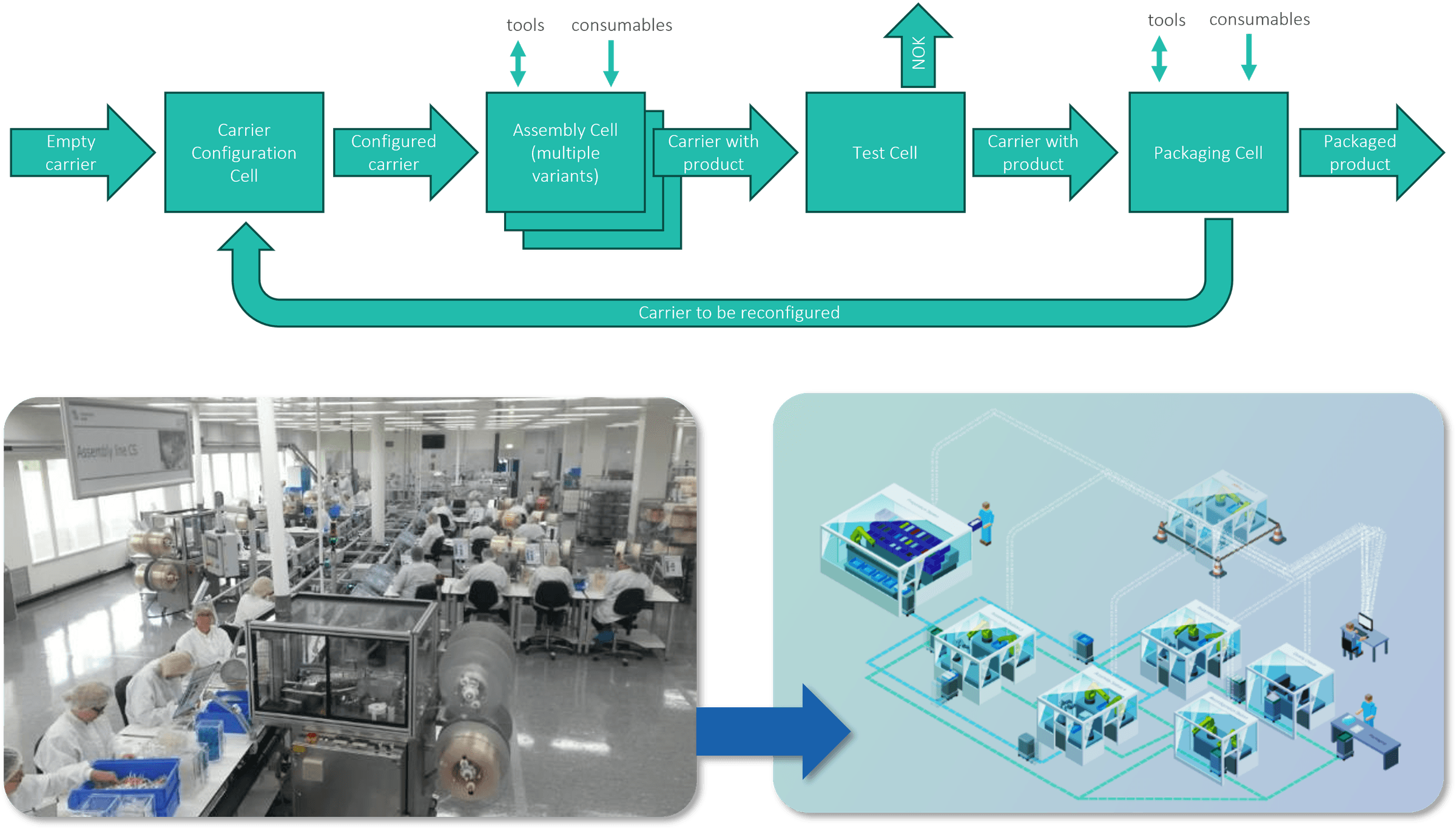

Revisiting the medical disposable example, one specific challenge was that precise fitting of deformable components required dedicated assembly tooling. Due to the high variation in physical layout of the tubing sets, each product configuration required a customized carrier to assemble all components, before rolling up the tubes to fit the product inside a pouch. To achieve this, a flexible tooling system was developed, to provide automated assembly of a unique carrier for a specific product configuration. This was done in a robotized carrier configuration cell, where product specific clamps and holders from a tooling stock were mounted on a breadboard tooling plate.

The transport system, in this case an Autonomous Mobile Robot (AMR), allows for any sequence of process cells to be visited. Product variants that do not require a certain process step can skip that process cell completely, to not waste space in its input buffer. Product variants equipped with multiple tubes can revisit the tube placement, clip placement and roll-up cells in sequence for each of the tubes.

The overall process flow is depicted, featuring tooling configuration, product assembly, testing and packaging. After the product is removed from the carrier, the carrier moves to the Carrier Configuration station to be re-configured for the next product type. The automated high-mix production line is capable of replacing a 60 FTE manual assembly operation by several highly automated process cells and an autonomous transport system.

4. Evolving operations

Now we have the end in mind, where do we begin? Typically, a green field scenario where you rebuilt the entire production line at once is not viable. Hence, successful implementation requires strategic planning of the transition.

The beauty of the flexible factory architecture is that it does not require automation. Yes, it is optimized for automation, but any of the process cells can be implemented in an automated, semi-automated or manual way. Even the transport system can initially be implemented by human-carried-trays for example. Both manual and automated implementations can coexist in an efficient way, allowing for a seamless evolution of operations rather than a revolution.

During development for example, an automated cell can operate alongside its manual counterpart until performance metrics are met. This approach avoids disruptions to day-to-day operations and enables gradual, measured adoption of automation. In cases it can be logical to keep the manual operated cell available next to the automated one. It can serve as a back-up for failures or during maintenance, or temporary increase production capacity when needed.

5. Staying ahead of competition

By strategically redesigning processes and adopting automation incrementally, innovators can unlock new levels of efficiency and innovation. Automation empowers high-mix production companies to stay competitive in a global market:

- Scale operations – flexibility to scale both the mix and volume of products to meet future demands

- Consistent quality – independent of availability, competency and experience of individuals

- Mass customization – products tailored to individual customers and made-to-order

In conclusion, the transition to automation in high-mix production companies is not merely a technological upgrade; it is a transformative strategy that enables businesses to thrive in an evolving market. By recognizing the symptoms of inefficiency and embracing a clear vision for automation, companies can secure their place as leaders in customization, quality, and agility.

contact.

Would you like to exchange thoughts about your production process? Please reach out so we can schedule an online meeting or plan a visit.

DEMCON Industrial Systems Groningen B.V.

Blauwborgje 31, 9747 AC GRONINGEN, Nederland