the need for sustainable solutions.

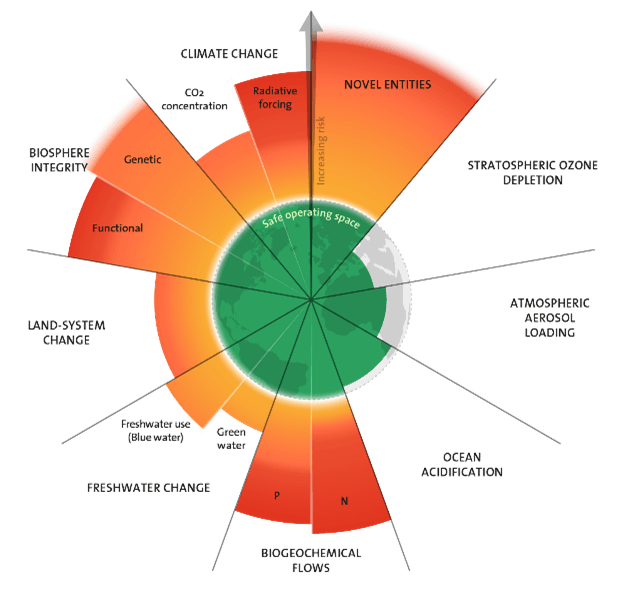

With Earth's boundaries being stretched beyond their limits, the call to rethink our supply chains has never been more urgent. Traditional methods of manufacturing have long relied on virgin resources, driving resource depletion and contributing to an unsustainable ecological footprint. By prioritizing circularity of materials—where resources are reduced, reused and recycled — industries can drastically lower their environmental impact. From start-ups to established giants in the production industry, the shift toward circular materials demands bold ideas, adaptive strategies, and a shared commitment throughout value chains. Successfully scaling these bold ideas is an imperative for safeguarding the planet for future generations.

If not for sustaining a livable planet, companies must also consider the geo-political implications of relying heavily on foreign resources. Global supply chains are increasingly vulnerable to disruptions caused by political instability, trade disputes, or conflicts between nations. By investing in circular materials and local sourcing, industries can enhance their resilience, reduce exposure to volatile international markets, and contribute to greater economic and environmental security on both a national and continental scale.

different innovators, the same challenge.

Irrespective of the size of a company, scaling-up an innovation is a not just a technical challenge. Organizational aspects as well as managing investment risks are key to successfully mature and deploy innovations at the right time.

For a start-up company, scaling-up (or down) at the right time is crucial for survival. In addition to the novel product, new production processes and possibly new production equipment need to be developed. With a limited team size this can become overwhelming rather quickly as demands fluctuate. With continuously changing requirements – both of the product itself, as well as the production capacity or constraints – flexibility is of vital importance until a successful market introduction delivers a solid revenue.

For a 1000 FTE production plant with the ambition to transitioning from virgin resources to circular materials. This transition has to occur without putting current operations at risk, as customers rely on your products being delivered with high quality and on time, regardless of your innovation roadmap. The team in charge of the innovation is often burdened with troubleshooting the current operations. Not only leading to continuous delays of the project, but also risking to overload your most valuable specialists.

In order to scale-up an innovative process, no matter whether it concerns manufacturing, recycling or sorting a resource stream, suitable equipment is needed. Often, existing equipment is not suited for a novel process and suppliers of standard equipment are not interested in providing the required modifications to their machines. Hence, the development of custom equipment is required to development the novel product or process.

the chicken-egg-problem.

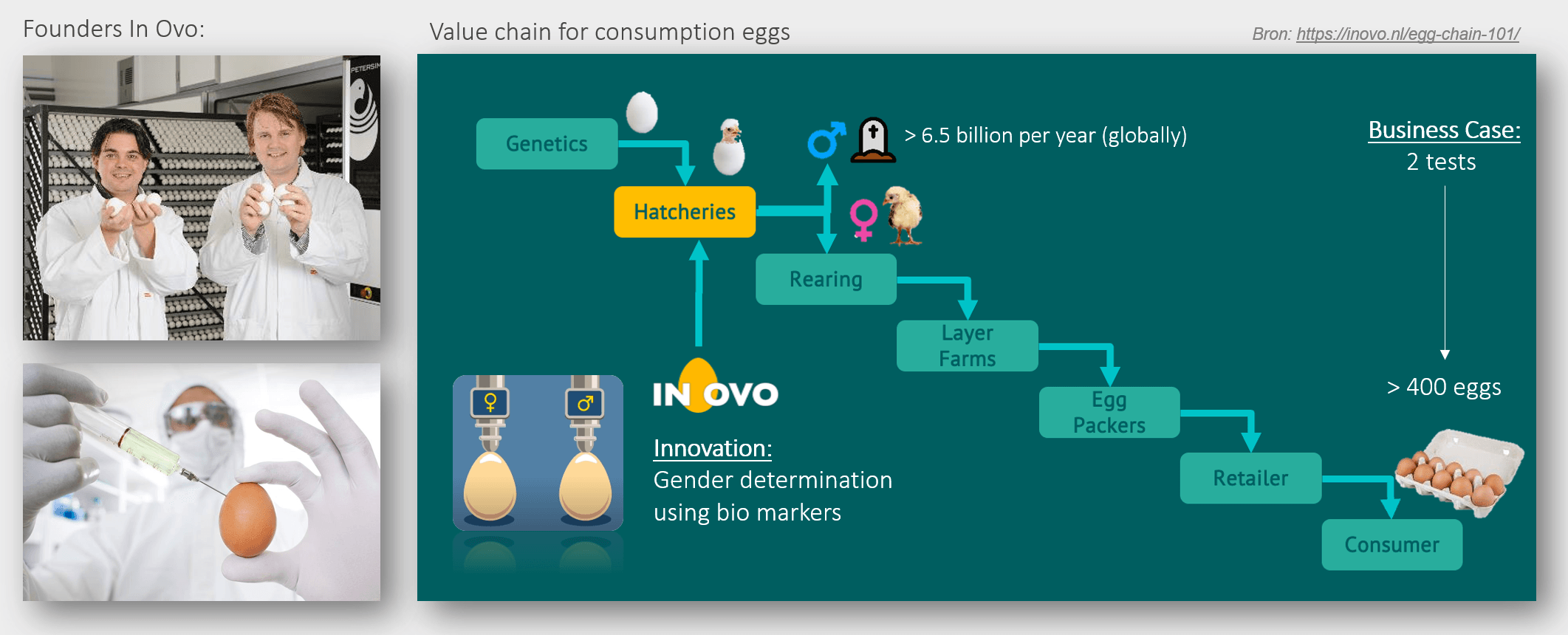

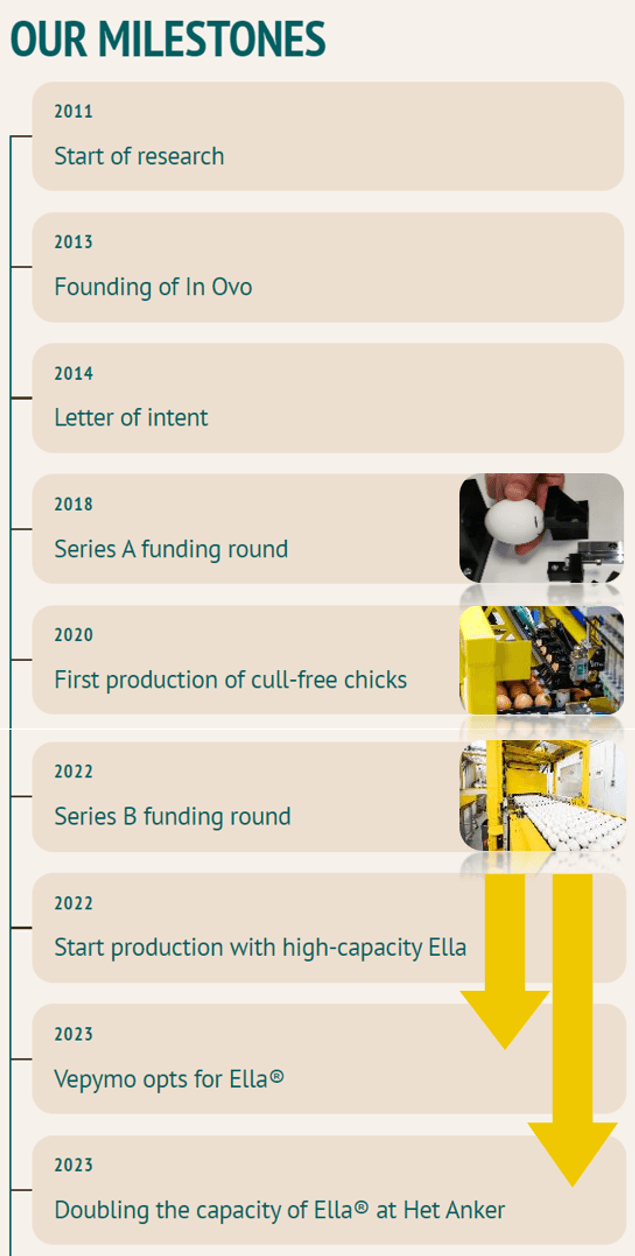

Now, let me introduce an example project. The start-up In Ovo came to Demcon with a novel technology to determine the gender of an unhatched chicken egg using chemical analysis. Currently billions of male chicks are culled yearly, because layer farms only require female chickens and this breed of chickens in not viable for meat production. Hence, their innovation can have a great positive impact on both animal welfare and sustainability.

But how to scale-up a process where a trained scientist carefully takes a small sample in a lab environment, to a viable operational situation, requiring:

- Increase sorting capacity from a few to thousands of eggs per hour

- Increased reliability of sampling, without damaging the embryo

- Prevent cross-contamination of samples to ensure accurate sorting

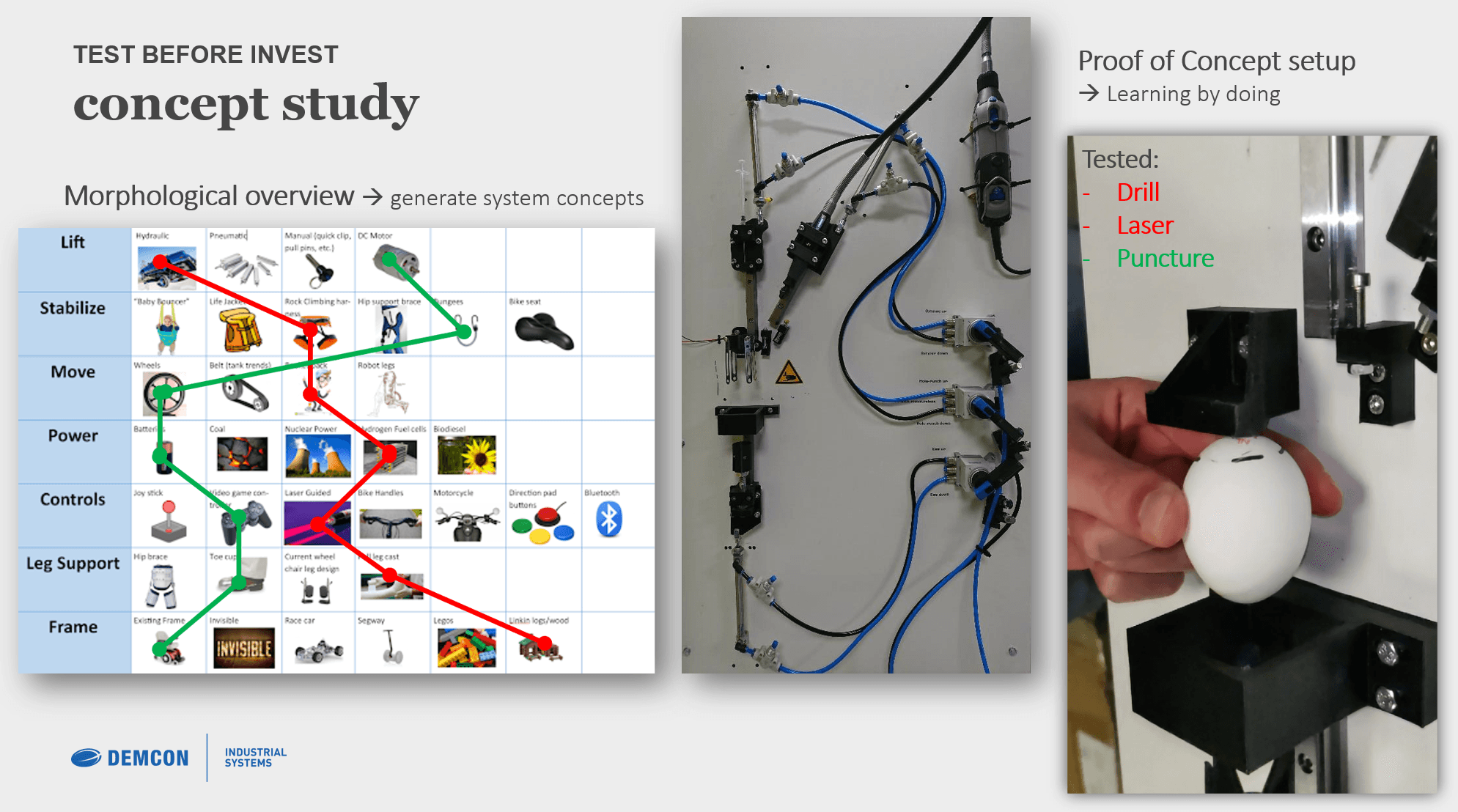

Now the actual chicken-egg-problem becomes apparent, because further maturing the technology requires new equipment, but developing new equipment requires a well-known and mature process.

iterative co-development cycles.

The following sections illustrate how we solve such a chicken-egg-problem together with our customer. While we iterate on the automation concepts and equipment design, our customer further researches and matures the core technology.

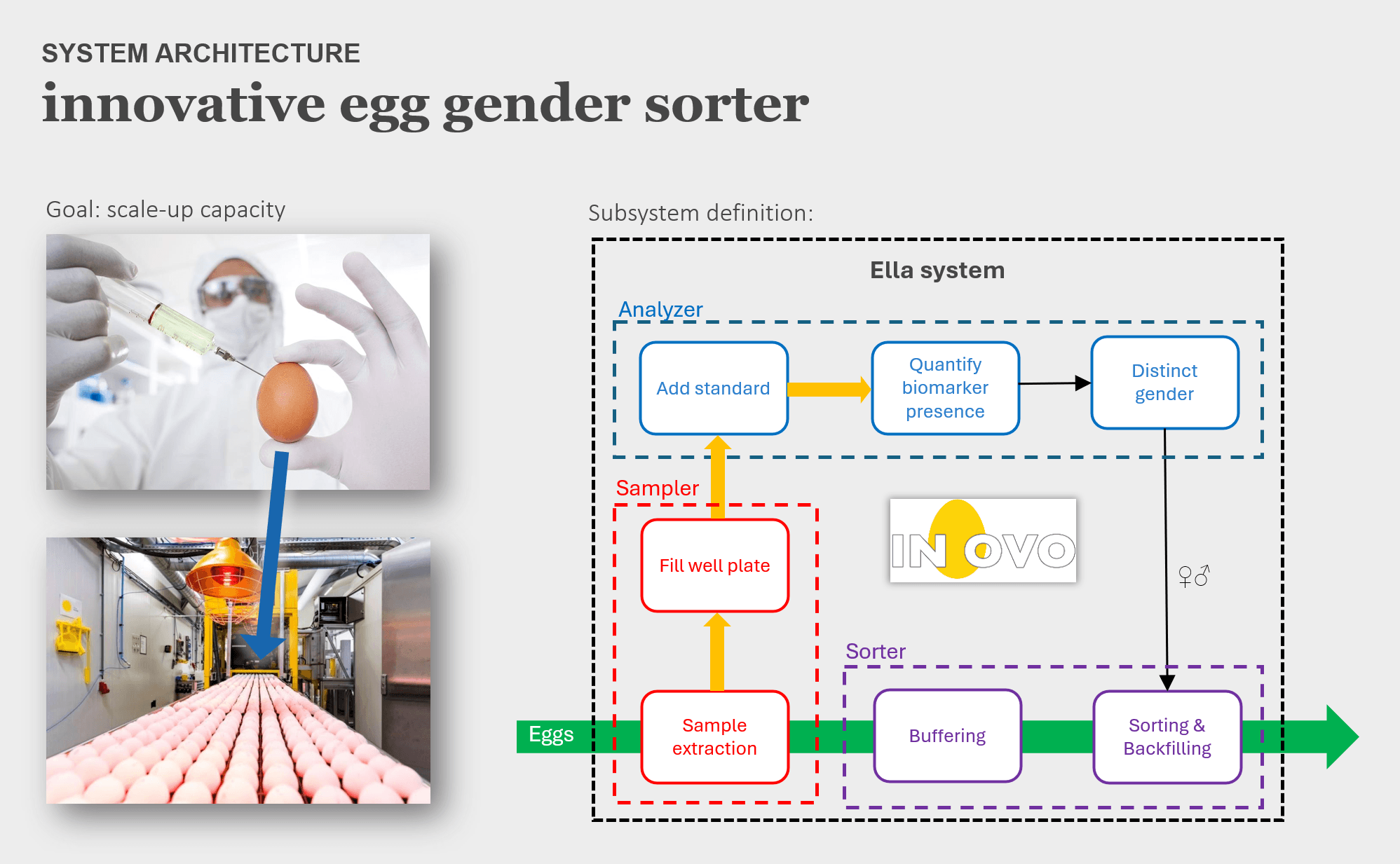

Using the experimental knowledge, the overall system design is completed. All subsystems are specified, such that commercially available products can be reviewed. Subsystems that are not commercially available enter a detailed engineering phase. In this case, the ‘Analyzer’ subsystem holds the core technology of biomarker detection and was further developed by In Ovo. The ‘Sample’ and ‘Sorter’ subsystems have been developed by Demcon.

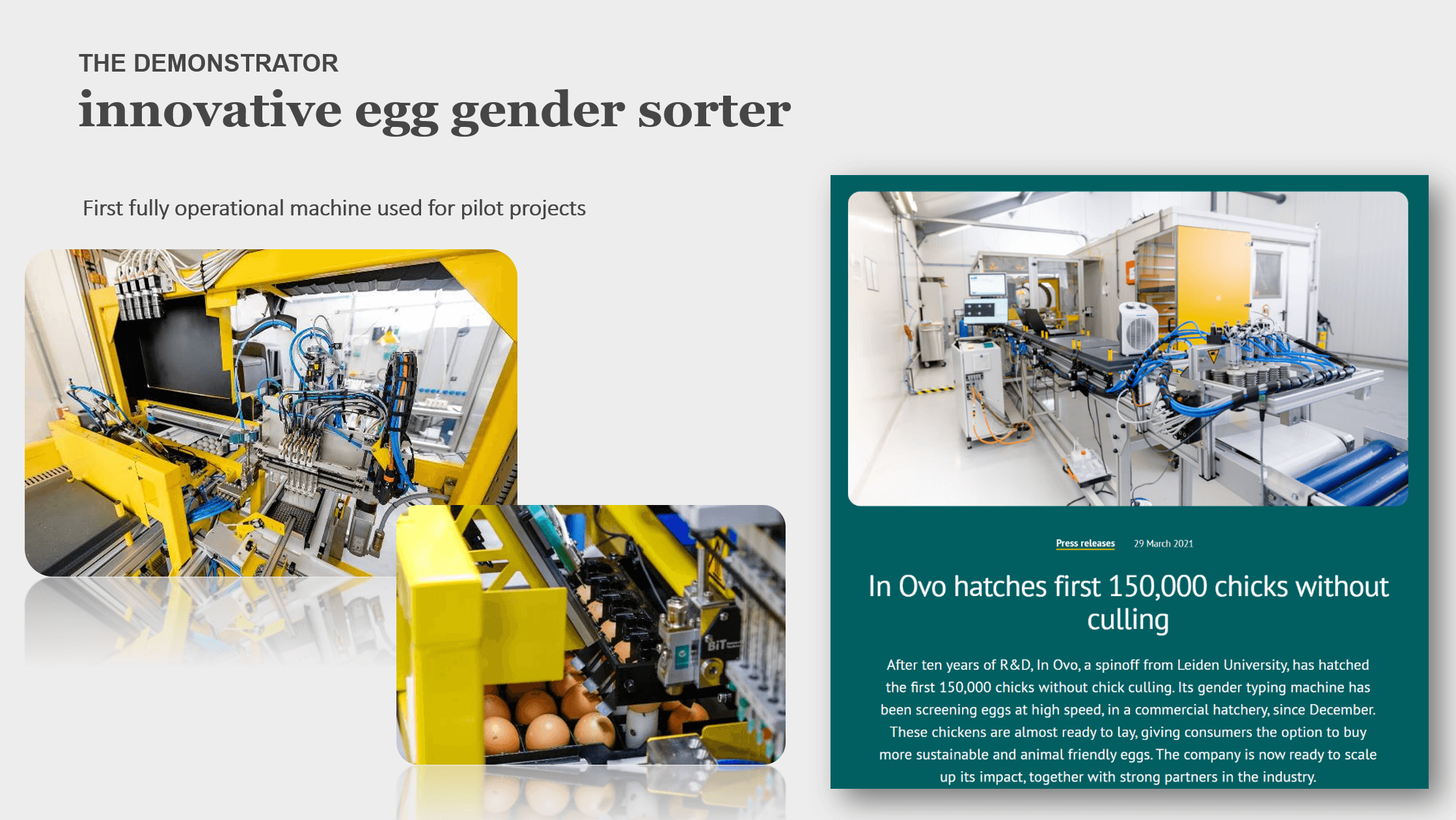

A first system was realized to test the technology in pilot projects at scale. The capacity was slightly reduced compared to the commercial goal, but for the rest all functionalities were integrated into this demonstrator system. With this milestone, In Ovo was able to raise to required funding to proceed to the next phase.

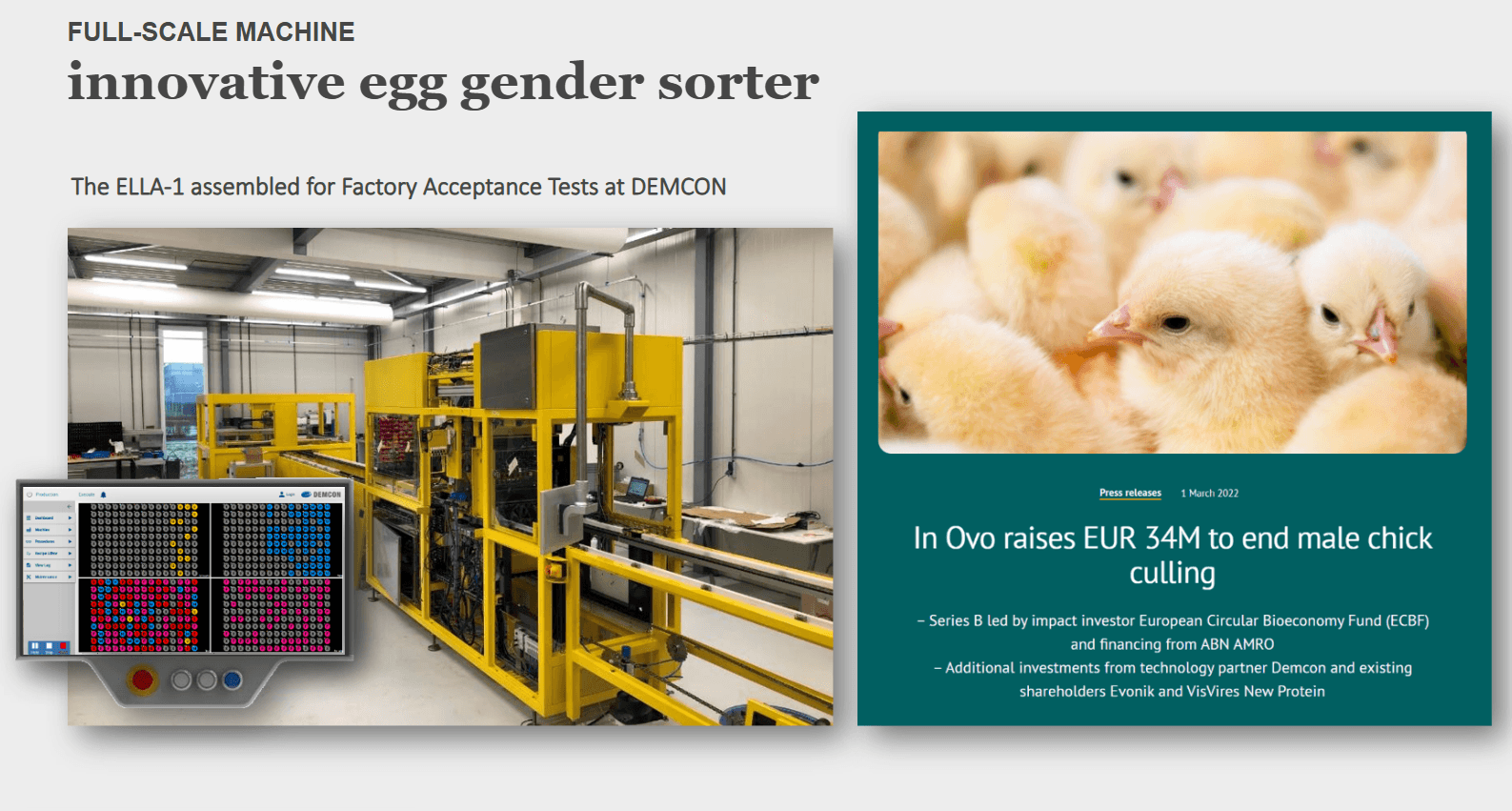

Next, the ‘Sampler’ and ‘Sorter’ for the full-scale machine were developed, built and tested at Demcon. Once functionally verified, the system was deployed at a launching customer for the operational validation, leading to another major milestone for In Ovo.

partner for production technology.

Through close collaboration, it is possible to co-develop new technology and the right equipment at each step of scaling. In summary, we were able to:

- Mature Technology – challenge the core technology to understand what works

- Scale Operations – meet the required capacity at every stage of development

- Secure Investments – achieve milestones to provide confidence to investors

contact.

Would you like to exchange thoughts about scaling your innovation? Please reach out so we can schedule an online meeting or plan a visit.

DEMCON Industrial Systems Groningen B.V.

Blauwborgje 31, 9747 AC GRONINGEN, Nederland