reproducible and standardized.

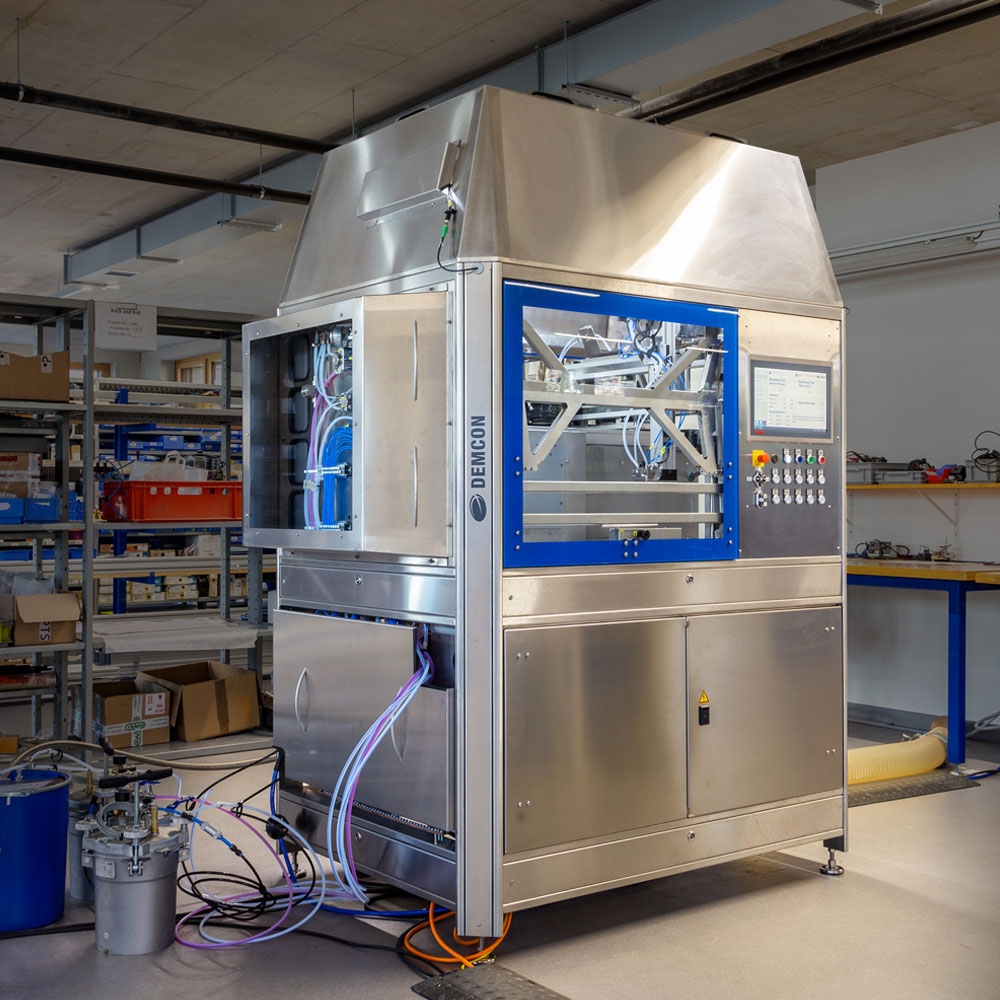

Until now, two-tone coatings on cars, for example, were always applied in two passes. To prevent overspray, adjacent areas were taped off. That was a labor-intensive job in an unhealthy environment. Dürr, a leading manufacturer of coating technology, has developed a solution for applying paint without overspray: OFLA, or ‘Oversprayfreie Lackapplikation’. Manufacturers who supply suitable paints want to be able to test them first on standardized substrates. We therefore built a test machine with a painting robot that performs the required movements reproducibly and extremely accurately. Dürr’s EcoPaintJet system is integrated into our machine, which is completely made of stainless steel.

highlights

- 3-axis paint robot with 600 mm x 400 mm x 400 mm range

- maximum painting speed 1 m/s

- reproducibility ±0.05 mm

- horizontal and vertical paint application

- ATEX-certified (zone 2)

best formulation.

Our paint testing spray booth simulates the movements of a painting robot at the coating line in a controlled, dust-free laboratory environment. To compare different paint formulations, the machine always performs exactly the same movement with high precision. Our machine processes both water-based paints and solvent-based paints and is explosion-proof (ATEX) in view of the latter category. For ATEX certification, our design provides a constant flow of clean air into the test cell. This air flow removes solvent and thus lowers the concentration to a safe level. With the machine’s comprehensive control, paint manufacturers can easily define their test programs and parameters to find the best formulation for their coating products.

“we contribute to sustainability.”

Our test machine is a building block in a development that has made the coating process more efficient and environmentally friendly. With the development of this machine, we contributed to innovation in the paint industry.